Understanding the Capability of an Optical Fibre Diameter Analyser in Modern Manufacturing

The optical Fibre Diameter analyser works as an essential tool in modern production, using precise, non-contact dimensions that are vital for maintaining rigid sector criteria. By leveraging advanced laser technology, these analysers not only make certain marginal signal loss but additionally boost the general efficiency of optical fibres. Their ability for real-time data handling permits producers to promptly address any type of inconsistencies from specifications, promoting a society of continual improvement. Comprehending the intricacies of this technology questions about its broader ramifications in making efficiency and quality control across different fields.

Significance of Optical Fibre Measurement

In modern manufacturing, the measurement of optical Fibre Diameter is crucial for making sure the performance and dependability of Fibre optic systems. Accurate Diameter dimension straight impacts optical performance, as variations can cause raised signal loss, minimized bandwidth, and lessened total effectiveness. The optical homes, consisting of light transmission and signal stability, are highly conscious the Fibre's Diameter, requiring accurate control during manufacturing.

In addition, standardization in Fibre Diameter is essential for compatibility and interoperability within diverse telecommunications networks. As these networks increase worldwide, maintaining harmony in Fibre features promotes smooth combination across different parts and systems. Furthermore, sticking to market criteria concerning Diameter tolerances is crucial for makers to meet governing requirements and consumer expectations.

Buying advanced measurement modern technologies not only boosts producing performance but additionally supports high quality guarantee processes, making it possible for manufacturers to determine defects early in production. This aggressive approach minimizes waste and guarantees that the last items meet rigid efficiency criteria. As a result, the relevance of optical Fibre measurement can not be overemphasized, as it acts as a foundation for high-grade, reputable Fibre optic systems, which are indispensable to modern interaction facilities.

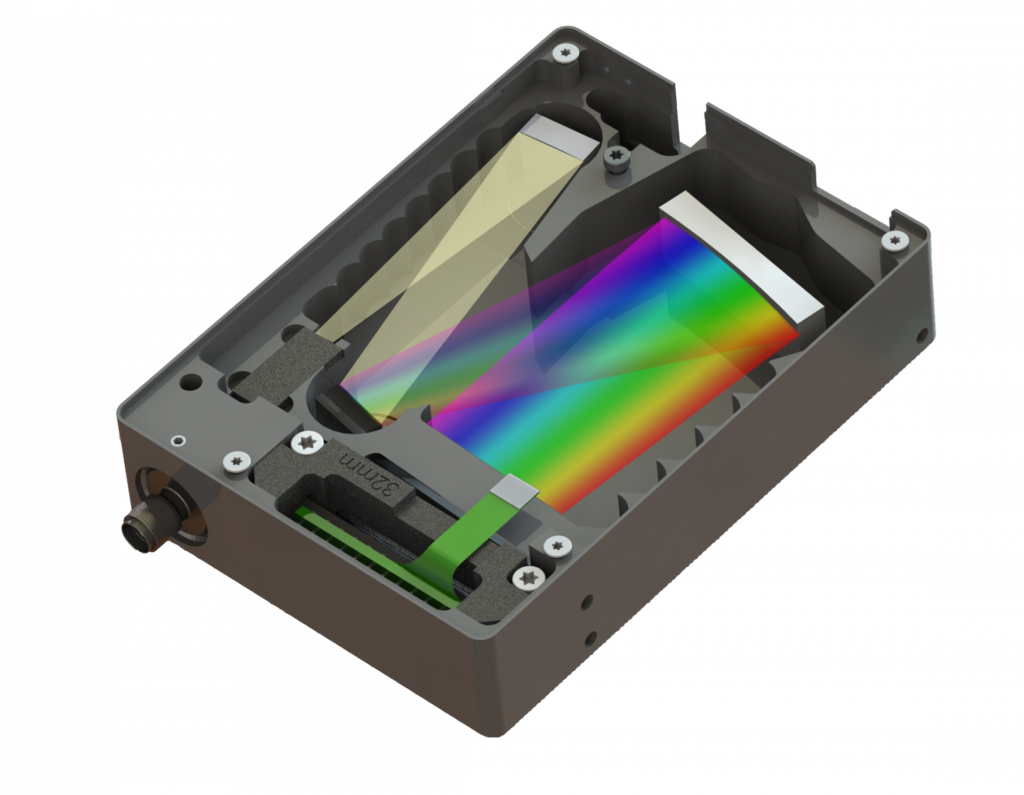

How Diameter Analysers Work

The core procedure counts on the concept of light scattering and representation. As the laser light beam strikes the Fibre, variants in Diameter reason adjustments in the light's intensity and wavelength (optical fibre diameter analyser). This information is processed in real-time making use of advanced algorithms that translate the optical signals right into exact Diameter measurements

Additionally, many Diameter analysers are furnished with numerous measurement points along the Fibre, enabling for a comprehensive assessment of Diameter consistency. The implementation of such modern technology dramatically enhances quality control in production, ensuring that optical fibres are generated to precise specs for ideal efficiency in their desired applications.

Trick Functions to Think About

When choosing an optical Fibre Diameter analyser, numerous vital functions call for cautious factor to consider to guarantee ideal performance and integrity. Initially, measurement precision is vital; the analyser ought to supply exact Diameter analyses, usually in micrometers, to satisfy rigorous production requirements. Furthermore, a wide measurement range boosts adaptability, accommodating different Fibre kinds and thicknesses.

An additional crucial function is the see this website analyser's speed. Quick measurement abilities enable increased throughput, crucial in high-volume production settings. Moreover, real-time information processing and responses capacities make it possible for prompt adjustments, enhancing top quality control.

Customer user interface and software program compatibility are additionally considerable factors to consider. An user-friendly user interface simplifies operation, while robust software program support helps with information analysis and assimilation with existing manufacturing systems. The ability to export information in various layouts can improve coverage and conformity efforts.

In addition, longevity and maintenance needs ought to be evaluated. An analyser built from top quality products will stand up to the rigours of a manufacturing setting, while ease of upkeep guarantees long life and reduces downtime. Consider the level of technological assistance and training provided by the maker, as this can significantly affect the reliable usage of the analyser in production settings.

Benefits in Production Efficiency

Enhancing manufacturing effectiveness pivots on the integration of sophisticated modern technologies, such as optical Fibre Diameter analysers. These instruments play a critical function in ensuring that optical fibres meet rigid top quality criteria, which is essential for ideal performance in different applications - optical fibre diameter analyser. By supplying real-time dimensions of Fibre Diameter, manufacturers can swiftly identify and correct variances from defined resistances, therefore minimizing waste and reducing the danger of malfunctioning items

Moreover, the early discovery of prospective concerns brings about minimized downtime and maintenance prices, thus maximizing resource appropriation. Eventually, the performance gets realized via the visit our website use of optical Fibre Diameter analysers add to a much more affordable manufacturing setting, making certain that companies can supply premium items while preserving cost-effectiveness and responsiveness to market needs.

Applications Across Industries

The adaptability of optical Fibre Diameter analysers expands beyond making efficiency, discovering applications throughout various markets that count on optical Fibre innovation. In telecoms, these analysers are essential for making sure the optimum performance of Fibre optic cords, straight impacting data transmission rates and network integrity. By properly determining Fibre sizes, drivers can reduce signal loss and boost total communication quality.

The clinical sector also profits substantially from these tools, particularly in the development of endoscopic tools and laser therapies. Exact Diameter dimensions are important for producing efficient optical fibers that are made use of in minimally intrusive treatments, boosting patient outcomes through enhanced imaging and treatment abilities.

In aerospace, the analysers play an essential duty in the manufacturing of light-weight, high-strength products, where Fibre optics are incorporated right into architectural elements for tracking and diagnostics. Furthermore, the vehicle market utilizes these devices to guarantee the stability of Fibre optic sensors that enhance safety and efficiency attributes in vehicles.

Verdict

In final thought, the optical Fibre Diameter analyser is essential for modern-day manufacturing, making certain exact measurements that copyright sector standards. The varied applications across numerous markets emphasize the analyser's relevance in promoting constant enhancement and data-driven decision-making within the production industry.

In modern-day manufacturing, the dimension of optical Fibre Diameter is essential for making certain the performance and integrity of Fibre optic systems. The value of optical Fibre measurement can not be overstated, as it serves as a structure for high-quality, trustworthy Fibre optic systems, which are important to modern-day communication facilities.

Diameter analysers employ sophisticated optical innovations to properly measure the Diameter of optical fibers.In addition, many Diameter analysers are furnished with numerous measurement points along the Fibre, enabling for a thorough assessment of Diameter consistency.The adaptability of optical Fibre Diameter analysers prolongs past producing effectiveness, locating applications throughout various industries that depend on optical Fibre innovation.